Introduction

Layer of Protection Analysis (LOPA) is a semi-quantitative risk assessment methodology used to analyze and assess the risks of high-consequence scenarios in process industries. It provides a structured approach to evaluating the adequacy of protective measures against potential hazard scenarios.

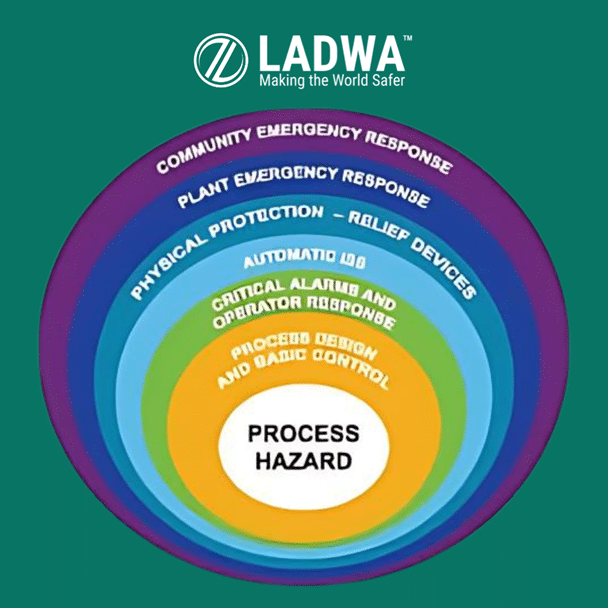

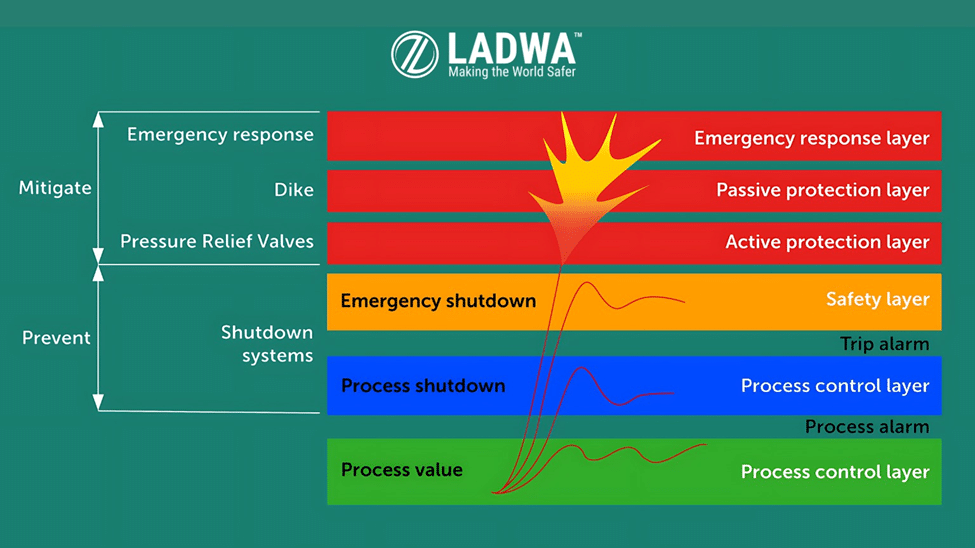

The foundation of LOPA lies in defense-in-depth. We implement multiple, independent layers of Protection to:

- Reduce the likelihood of incidents occurring.

- Mitigate the consequences if an incident does occur.

- Ensure that no single failure can lead to a catastrophic event.

- Process Design

- Basic Process Control Systems (BPCS)

- Critical Alarms and Operator Response

- Automatic Shutdown Systems (e.g., Safety Instrumented Functions)

- Physical Protection (pre-release), such as pressure relief valves

- Physical Protection (post-release), such as dikes

- Emergency Response

LOPA is typically employed:

- After a HAZOP study to further analyze high-risk scenarios

- When determining the required Safety Integrity Level (SIL) for Safety Instrumented Systems

- To justify risk reduction measures or demonstrate ALARP (As Low As Reasonably Practicable)

During the design phase of new processes or significant modifications

While HAZOP (Hazard and Operability Study) identifies potential hazards and operability issues, LOPA builds upon HAZOP results by:

- Quantifying the risk of specific hazard scenarios

- Evaluating the effectiveness of existing safeguards

- Determining if additional risk reduction measures are needed

- Identify hazard scenarios (often from HAZOP studies)

- Estimate the severity of consequences

- Identify Initiating Events (IEs) and their frequencies

- Identify Independent Protection Layers (IPLs)

- Estimate the Probability of Failure on Demand (PFD) for each IPL

- Calculate the mitigated event frequency

- Compare results against risk tolerance criteria

- Recommend additional safeguards if needed

Establish company risk tolerance criteria.

Identify hazards and consequences of concern.

- Identify Initiating Events (IEs) and their frequencies.

- Assess severity based on the company Risk Matrix or consequence analysis.

- Identify IPLs and their PFDs, ensuring independence, effectiveness, and audibility.

- Assess likelihood by multiplying IEF, PFDs of IPLs, and probabilities of enabling conditions and conditional modifiers.

- Evaluate if the risk meets the tolerance criteria.

- If not, identify and suggest additional IPLs for implementation

- Requires extensive knowledge and experience for proper application

- Scenario-based risk assessment, not directly estimating Individual Risk (IR)

- Results may vary between organizations due to different risk tolerance criteria and LOPA bases.

- Potential for uncertainties in results due to variations in values used or assumptions made

- Simplification of complex scenarios may lead to overlooking some risks.

- Reliance on generic failure rate data may only sometimes reflect site-specific conditions.

- Difficulty in accounting for human factors and organizational influences

- Limited ability to address uncertainty in data and assumptions

- Initiating Event (IE): A failure that starts the sequence of events

- Independent Protection Layers (IPLs): Control measures that can prevent the IE from propagating

- Probability of Failure on Demand (PFD): Failure probability of an IPL when called upon to act

- Enabling Conditions: Operating conditions necessary for the IE to propagate

- Conditional Modifiers: Probabilities of conditions required for the hazardous outcome to occur

- Misunderstanding demand modes (low demand vs. high demand/continuous)

- Incorrect application of failure values

- Neglecting to perform sensitivity analysis to address uncertainties

Conclusion

LOPA is a powerful tool in the process safety toolkit, bridging the gap between qualitative hazard identification and detailed quantitative risk assessment.

Safety professionals can use LOPA to enhance process safety and make informed risk management decisions by understanding its strengths, limitations, and potential pitfalls.

This comprehensive guide provides a solid foundation for understanding and implementing LOPA in your organization. Remember, proper application requires expertise and experience, so consult with qualified professionals when conducting LOPA studies.