Introduction

When working in environments where extreme heat is a constant hazard, selecting the appropriate heat-resistant gloves is not just a matter of comfort—it’s a critical aspect of worker safety. Heat-resistant gloves are specifically designed to protect the wearer’s hands from high temperatures commonly encountered in welding, metalworking, and other industrial applications. These gloves are crafted from specialized materials that can withstand extreme heat, offering protection against burns, molten materials, and even open flames.

The importance of choosing the right heat-resistant gloves cannot be overstated. Not only do they shield workers from immediate harm, but they also enhance grip and dexterity, enabling workers to perform their tasks more efficiently and safely. Proper protection reduces the risk of injury and contributes to long-term health by preventing chronic conditions associated with repeated exposure to high temperatures.

Ladwa Solutions Inc., a prominent manufacturer and supplier of safety gloves and industrial safety products, understands the critical role that proper safety gear plays in the workplace. With a wide range of heat-resistant gloves tailored to meet various industry needs, Ladwa is committed to enhancing worker safety and ensuring that businesses have access to top-quality protective equipment. Whether you’re handling hot tools or working in extreme conditions, Ladwa Solutions Inc. offers reliable solutions to keep your hands safe while maintaining the dexterity and grip needed for precision work.

What is Heat Resistant Gloves?

Heat-resistant gloves allow your workers to operate with cautious ease while protecting themselves from contacting dangerously hot surfaces and conditions. Unfortunately, even with protection available, heat hazards caused 7,020 thermal burns to workers’ hands, wrists, and arms in 2019.

So whether your workers handle hot textiles, maintain pipes and heating equipment, or do other hot handling work, there are a number of options you can consider to find the best protection.

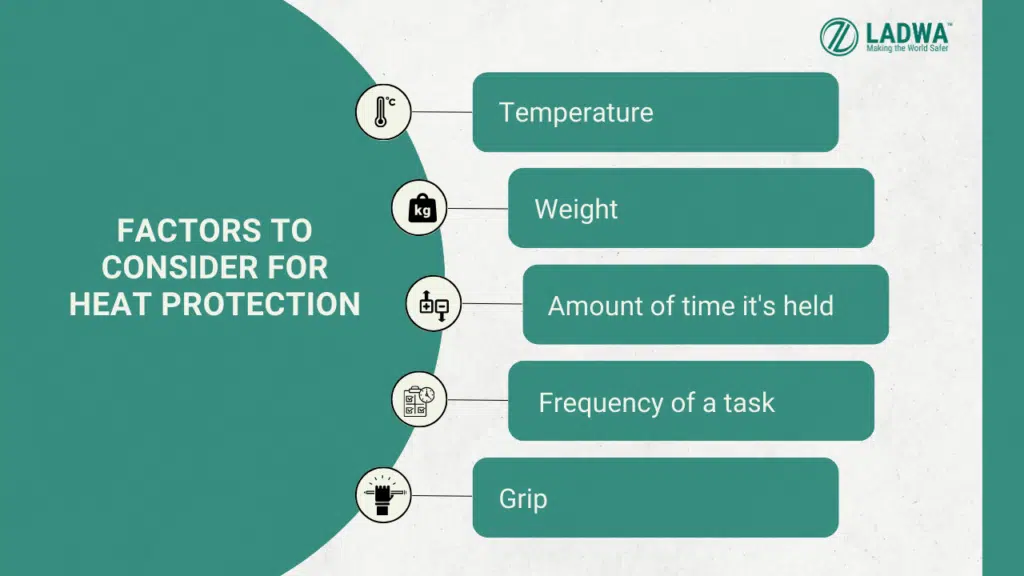

Factors to Consider for Heat Protection

The right heat-resistant glove for your application depends on a number of factors involving the hot objects being handled:

- Temperature

- Weight

- Amount of time it’s held

- Frequency of a task

- Grip

The more of these you have in the application, the higher heat protection you’ll need.

Trivia On Heat-Resistant Gloves

Heat-resistant gloves are essential for protecting hands in high-temperature environments, such as welding, cooking, and industrial processes.

Here are Some Trivia Facts about Heat-Resistant Gloves:

- Layered Protection: Many heat-resistant gloves feature multiple layers for added protection. For example, they may have an outer layer for abrasion resistance and an inner layer for insulation.

- Coatings: Some heat-resistant safety gloves have special coatings, such as silicone or neoprene, to improve grip and dexterity while maintaining heat resistance.

- Thumb Design: The thumb on a heat-resistant glove is often designed separately to allow for better mobility and grip. This design is known as a “keystone thumb.”

- Length Options: Heat-resistant gloves come in various lengths to protect different parts of the arm. Some are short, while others extend past the wrist to offer forearm protection.

- Regulatory Standards: In many industries, heat-resistant gloves must meet specific safety standards and regulations to ensure they provide adequate protection for workers.

- Durability: Heat-resistant gloves are designed to be durable and long-lasting, even in harsh working conditions. Proper care and maintenance can extend their lifespan.

- Heat-Resistant Mittens: In addition to gloves, heat-resistant mittens are also available and offer superior insulation and protection for the entire hand.

- Industry Variations: Different industries have their own unique requirements for heat-resistant gloves. For example, glassblowers may need gloves with extra dexterity, while firefighters require gloves that can withstand extreme heat.

Different Heat-Resistant Materials Provide Varying Degrees Of Protection

Heat-resistant materials vary in their protective qualities. Some offer high levels of durability and heat resistance, while others provide moderate protection or insulation. Each material type is designed to meet specific safety needs in high-temperature environments, ensuring effective protection and performance. Here are a few materials given below:

- Leather

Pros: Has natural flame-resistant properties and good abrasion protection. Can be one of the more affordable options to choose from.

Cons: Traps heat close to the skin, can harden from heat over time, and doesn’t have a high degree of cut resistance. Provides less dexterity than some other glove materials.

- Terrycloth

Pros: Looped knitting traps air and creates more insulation. Has some degree of cut and abrasion protection and is comfortable to wear.

Cons: May absorb liquids and become saturated, not as dexterous as other materials.

- Aramid

Pros: Inherently flame-resistant and has a high degree of cut resistance and dexterity.

Cons: Can be one of the more expensive options to choose from.

- Acrylic

Pros: Glove liners add insulation for high heat contact as well as improved durability.

Cons: Can feel heavy when formed as a glove shell.

- Aramax

Pros: Draws heat away from the skin, and can be designed for added flame-resistance. Great for warm environments where flames and sparks are present.

Cons: Not designed for high-heat applications.

Different Degrees of Protection in Heat-Resistant Gloves

Once you’ve determined your needs and the best materials, it’s time to consider whether workers need any specialized protection from other hazards in their application. Different hazards need different solutions, so your workers may need a glove with one or multiple protective features.

Fundamental Heat Protection

For basic heat protection without any specialized features for hazards like molten liquids, common materials can be combined to provide different levels of contact protection. Aramid yarns can be machine-knit into a thinner, more form-fitting glove that delivers different levels of heat resistance.

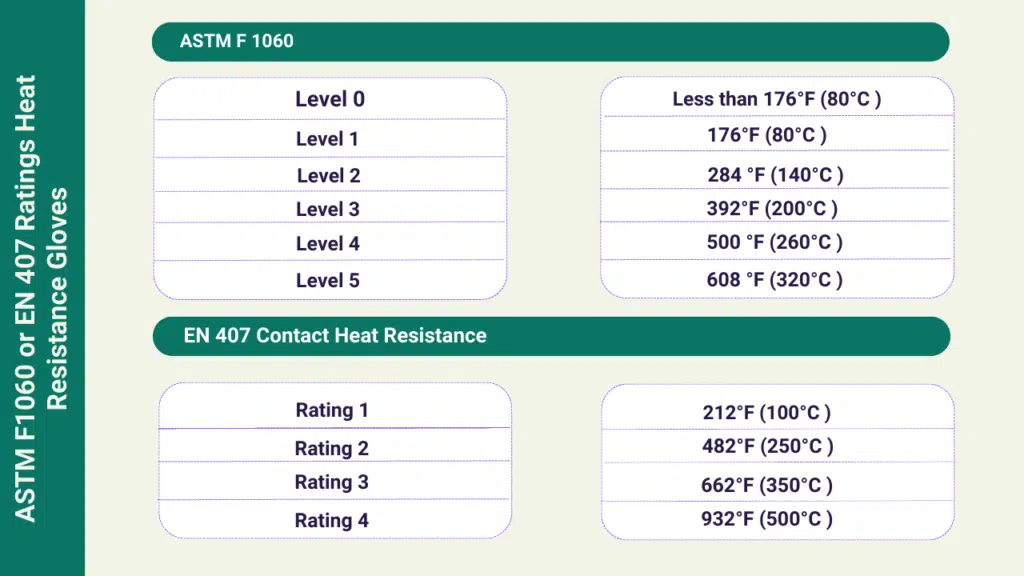

Compare different heat-resistant materials and keep an eye on their ASTM F1060 (according to the ANSI 105 standard) or EN 407 ratings to find a glove with heat resistance to match your application.

Heat Dissipation

For higher heat applications such as handling hot steel or ceramic molds, if a glove can’t disperse built-up heat over time, heat stress will collect within the glove and make it less comfortable. Machine-knit gloves allow for more breathability by dispersing heat through the back of the glove.

Cut and Laceration Protection

Your workers may need a glove with durable cut resistance and abrasion protection on top of proper heat resistance if they work with cut hazards. New gloves are available with cut-level protection to defend against sharp edges in addition to hot surfaces.

Types of Grips and Palm Coatings

Applications that require more dexterity and hand-movement such as grabbing a hot part out of an oven have led to the development of high-strength, heat-resistant gloves with more grip and control for handling hot and heavy materials. Added features such as nitrile-based palm dots on top of a nitrile or silicone palm coating further insulate a worker’s hands while simultaneously improving the glove’s grip.

Heat-Resistant Gloves with Multiple Levels of Protection

Depending on the job, you might need a glove that protects against all of these things! The best all-around heat-resistant gloves for worker use a combination of material layers to protect to Level 5 ASTM F1060 (according to the ANSI 105 standard) or Level 4 EN 407 contact heat certifications for the highest standardized levels of heat-resistant protection.

They can also provide cut resistance, versatile finger movement, added grip, and protection from heat, all contained within a breathable shell that allows for the transfer of heat.

Consider your application and let workers try a few gloves out for themselves. With a little testing and knowledge, the protection your workers need can always be close at hand!

Conclusion

In conclusion, when it comes to selecting the right heat-resistant gloves for your application, thorough consideration of the factors discussed in this comprehensive guide is essential. Your choice should prioritize safety, comfort, and suitability for the task at hand. Whether you are working with high-temperature ovens, welding equipment, or any other heat-intensive process, the appropriate gloves will not only protect your hands but also enhance your overall productivity.

Investing in high-quality heat-resistant gloves is a proactive step toward creating a safer workplace and protecting the long-term health of your workforce. Ladwa Solutions Inc. is your trusted partner in industrial safety products, offering a comprehensive range of heat-resistant gloves designed to meet the demands of various industries. With Ladwa, you can ensure that your team is equipped with the best protection available, without compromising on comfort or performance.

Don’t compromise on safety—explore Ladwa’s offerings today and take the first step toward a safer, more productive work environment. Visit our website or contact us to learn more about how we can help safeguard your workforce.